Views: 222 Author: Leah Publish Time: 2025-10-20 Origin: Site

Content Menu

● Handle Materials and Ergonomics

● Legal Considerations for Custom OTF Knives

● Quality Control and OEM Manufacturing Standards

● Why Choose Yangjiang Ruizhen Industry and Trade Co., Ltd. for Custom OTF Knives?

● Frequently Asked Questions (FAQ)

>> 1. What makes Custom OTF Knives different from regular folding knives?

>> 2. How do I maintain my Custom OTF Knife for long-term use?

>> 3. Are Custom OTF Knives legal everywhere?

>> 4. Can I order Custom OTF Knives with specific branding?

>> 5. What materials are best for a durable Custom OTF Knife handle?

In the world of outdoor enthusiasts, collectors, and tactical gear users, custom OTF knives stand out for their unique design, functionality, and craftsmanship. At Yangjiang Ruizhen Industry and Trade Co., Ltd., we specialize in producing high-quality OEM Custom OTF Knives for overseas brands, wholesalers, and manufacturers. This article explores the top features you should look for when choosing a Custom OTF Knife, helping you make an informed decision for your next purchase or partnership.

An OTF (Out The Front) knife is a type of automatic knife where the blade deploys and retracts from the front of the handle by sliding a switch or button. Custom OTF Knives are tailored knives that offer personalization in blade material, handle design, deployment mechanism, and overall finish. Due to their precise engineering, these knives are favored for rapid blade deployment in tactical, survival, and utility contexts.

The blade is the most critical part of a Custom OTF Knife. The choice of steel impacts sharpness, durability, corrosion resistance, and ease of maintenance.

- High Carbon Stainless Steel: Combines strength and rust resistance, ideal for outdoor use.

- D2 Tool Steel: Offers excellent edge retention, great for heavy-duty tasks.

- S35VN Stainless Steel: High-end steel known for superb sharpness and flexibility.

Using high-grade steel not only enhances the performance of the knife but also ensures longevity. For outdoor scenarios where exposure to moisture and rough use is common, corrosion resistance becomes crucial. This makes stainless steel varieties like S35VN particularly popular.

Blade geometry directly affects the knife's utility and effectiveness for the intended tasks. Popular blade shapes in Custom OTF Knives include:

- Double-Edged Dagger: Perfect for thrusting and tactical precision. This symmetrical blade provides a sharp edge on both sides, useful in combat or quick piercing tasks.

- Drop Point Blade: Known for strength and versatility, it excels at slicing and general utility work. Its convex curve provides durability.

- Spear Point: Offers a balanced combination of piercing power and cutting ability, making it attractive for both tactical and survival uses.

The choice of blade shape should match the user's primary application, whether that's self-defense, routine cutting, or outdoor survival.

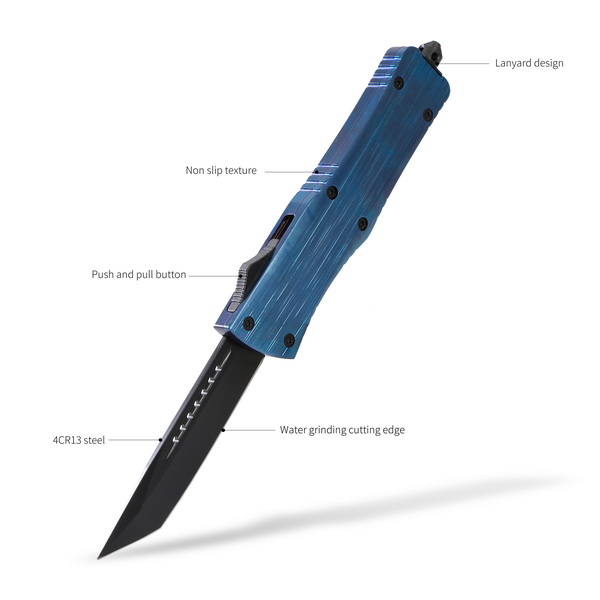

A defining feature of Custom OTF Knives is their fast and smooth blade deployment from the front of the handle. The quality of the deployment mechanism strongly influences the user experience.

- Smooth Slide Action: The blade should deploy and retract seamlessly with minimal force, enabling quick one-handed operation.

- Reliable Locking System: Ensures the blade locks securely in place during use to avoid accidents.

- Safety Lock Feature: Prevents unintended blade release, enhancing user safety.

Manufacturers often use precision engineering and quality materials for blades and internal components to guarantee consistent performance and durability after repeated use.

Since the handle provides grip and stability, its material and design are essential. Common materials include:

- Aluminum Alloy: Offers a lightweight yet sturdy handle that withstands heavy use.

- G10 Fiberglass Composite: Known for its excellent grip texture, even in wet conditions, which is important for safety and effectiveness during demanding tasks.

- Titanium: Preferred for its extreme strength, corrosion resistance, and premium feel, albeit at a higher cost.

Ergonomics also matter: well-contoured handles reduce hand fatigue during extended use, and textured surfaces improve grip security. In custom designs, manufacturers may add features like finger grooves, jimping (textured ridges), or rubber inserts to enhance comfort.

Blade size impacts portability, legal restrictions, and utility:

- Compact Blades (2–3 inches): Ideal for EDC (Everyday Carry), they balance concealment and functionality.

- Medium Blades (3–4.5 inches): Suited for tactical, survival, or outdoor applications requiring more cutting power.

Weight affects handling: a lightweight knife offers faster movements, while a heavier blade can provide more control and power for cutting tasks. The ideal Custom OTF Knife balances these factors to meet the user's preferences and use environment.

Custom OTF Knives excel in providing personalization, making them particularly attractive for brands and collectors.

- Engraving and Logos: Personalize knives with company logos, names, or unique designs to enhance brand recognition.

- Color Variations: Customize handle scales, blade coatings, and deployment switches with colors that match branding or aesthetic preferences.

- Accessories: Integration of features such as glass breakers, pocket clips, lanyard holes, or tactical studs expands a knife's functionality.

This ability to tailor each component to specific needs or branding requirements offers a competitive advantage for wholesalers and manufacturers.

A well-made Custom OTF Knife should endure harsh conditions and maintain performance over time. Durability largely depends on the quality of the blade steel, handle materials, and the internal sliding mechanism.

To keep a Custom OTF Knife in prime condition:

- Regularly clean the blade and sliding mechanism to remove dirt, debris, and moisture.

- Lubricate the sliding parts to maintain smooth action.

- Periodically check and tighten screws or fasteners to prevent loosening.

Proper maintenance prolongs the life of the knife and ensures safety and reliability during use.

Automated knives like OTF models fall under strict regulations in many countries. Legal restrictions can affect ownership, carrying, and use depending on local laws.

Before purchasing or importing Custom OTF Knives, users must:

- Verify the local laws regulating automatic blades.

- Check import restrictions in their country.

- Inform themselves about permissible blade lengths and requirements for concealed carry.

Manufacturers and wholesalers must also stay informed about these legal frameworks to comply with export and distribution regulations.

When sourcing Custom OTF Knives from overseas manufacturers like Yangjiang Ruizhen Industry and Trade Co., Ltd., quality control is paramount. Reliable factories use:

- Rigorous material selection and testing.

- Strict assembly procedures.

- Functional testing of blade deployment and locking mechanisms.

- Visual inspections for finish and craftsmanship.

OEM partners should prioritize suppliers with certification adherence, consistent product quality, and capacity for customization to align with brand standards.

Yangjiang Ruizhen Industry and Trade Co., Ltd. brings decades of experience in outdoor knife production with a focus on precision, durability, and customization. Our OEM services provide:

- A wide range of blade steels and handle materials.

- Custom branding options tailored to global markets.

- Advanced production technology ensuring smooth blade action and longevity.

- Strict quality management meeting international standards.

Partnering with us guarantees access to premium Custom OTF Knives backed by expertise in design and manufacturing.

A great Custom OTF Knife is a blend of precision engineering, superior materials, and thoughtful design. When choosing one, focus on blade quality, deployment reliability, handle ergonomics, and customization options to suit your specific needs. At Yangjiang Ruizhen Industry and Trade Co., Ltd., we take pride in manufacturing premium Custom OTF Knives tailored to meet the demands of overseas brands, wholesalers, and manufacturers. With the right Custom OTF Knife in hand, you gain a reliable tool perfectly suited for outdoor adventures, tactical use, or everyday personal protection.

Custom OTF Knives deploy their blade straight out of the handle via an internal sliding mechanism, offering faster one-handed deployment compared to traditional folding knives that pivot open.

Regularly clean the blade and sliding components, lubricate the mechanism, and check screws or fasteners for tightness to ensure smooth operation and durability.

No, laws vary by country and region. Always check local regulations before purchasing or carrying an automatic OTF knife.

Yes, OEM services provide customization including logos, engravings, color options, and accessory choices to meet your branding needs.

Aluminum alloy, G10 fiberglass composite, and titanium are the most popular choices due to their strength, corrosion resistance, and excellent grip properties.

How to Verify Authenticity and Quality in Automatic OTF Knife Purchases

Choosing an Automatic OTF Knife for Tactical vs Everyday Use

The Benefits of Same-Day Shipping When Ordering Automatic OTF Knives

What Sets Premium Automatic OTF Knives Apart From Budget Alternatives

How to Maintain Peak Performance of Your Automatic OTF Knife

What Consumers Should Know About Automatic OTF Knife Blade Deployment

Customization Options in Automatic OTF Knives: OEM and ODM Explained