Views: 222 Author: Leah Publish Time: 2025-10-20 Origin: Site

Content Menu

● Introduction to Custom OTF Knives

● Materials Matter: Blade Steel and Handle Composition

>> Blade Steel

● Precision Crafting: Why Custom Matters

● Mechanism Quality: The Heart of OTF Knives

● Ergonomics and Safety Features

● Popular Styles and Custom Options

● How to Choose the Right Custom OTF Knife

● Frequently Asked Questions (FAQ)

>> 1. What steel type is best for a custom OTF knife?

>> 2. Can I customize the blade length and design?

>> 3. How do I maintain the OTF knife mechanism?

>> 4. Are custom OTF knives legal to carry?

>> 5. What is the typical turnaround time for custom orders?

In the world of outdoor tools, custom OTF knives stand out for their precision, design, and functionality. At Yangjiang Ruizhen Industry and Trade Co., Ltd., we take pride in manufacturing top-tier knives that suit the needs of brands, wholesalers, and production companies globally. Understanding what defines a high-quality custom OTF knife helps buyers get the best value and performance.

An OTF (Out-the-Front) knife features a blade that deploys and retracts straight out of the handle's front via a sliding mechanism. This design allows quick, one-handed blade deployment, favored in tactical, survival, and everyday carry scenarios.

Key characteristics of an OTF knife include:

- Smooth spring-assisted blade action that enables fast deployment

- Compact and ergonomic handle design for comfortable grip and control

- Durable components built to withstand rigorous usage in outdoor conditions

OTF knives are prized for their convenience and tactical efficiency, making them popular choices for operators who need swift and reliable blade deployment.

The quality of materials used in custom OTF knives directly impacts durability, corrosion resistance, edge retention, and aesthetic appeal.

The blade steel is the heart of the knife's performance. High-quality options include:

- S35VN or S30V stainless steel: These premium steels offer excellent edge retention, toughness, and strong corrosion resistance. They perform well in outdoor and wet environments.

- D2 tool steel: A semi-stainless steel that combines hardness and wear resistance at a more affordable price point. It requires more maintenance to prevent corrosion.

- M390 or CTS-204P steel: High-end powder metallurgy steels known for exceptional wear resistance, edge retention, and toughness. Ideal for custom knives where superior performance is needed.

The choice of steel affects how often you need to sharpen the blade and how durable the edge will be in heavy use.

The handle provides grip and structural integrity. Recommended materials include:

- G10 fiberglass laminate: Lightweight, waterproof, and extremely durable with good grip texture.

- Carbon fiber: Offers a luxurious appearance, very strong, and lightweight but more expensive.

- Anodized aluminum: Provides a balance of weight, strength, and corrosion resistance with customizable colors and finishes.

The right handle material enhances comfort during extended use and boosts the knife's overall resilience.

Custom manufacturing lets users tailor every element of the OTF knife to their specific needs. Unlike mass-produced knives, customized models offer:

- Tailored blade length, shape, and thickness to suit particular tasks.

- Unique blade finishes such as stonewash, satin, or black-coated for aesthetics and rust resistance.

- Personalized engraving or logos to reflect your brand identity.

- Weight distribution optimized for better control and less fatigue.

Yangjiang Ruizhen Industry and Trade Co., Ltd. specializes in precision workmanship and OEM customization, ensuring every knife matches exact client specifications while maintaining high-quality production standards.

An OTF knife's defining feature is its blade deployment mechanism, which must be flawless to guarantee reliability and safety. Crucial factors include:

- Smooth, quick, and consistent blade deployment and retraction without jamming

- A robust locking mechanism that firmly holds the blade in the open position to prevent accidental closure during use

- Resistance to dirt and debris interference, ensuring longevity in demanding environments

- Ease of maintenance allowing cleaning and lubrication without partial disassembly

A poorly constructed mechanism compromises both functionality and user safety. Quality custom OTF knives undergo extensive testing to meet or exceed industry standards.

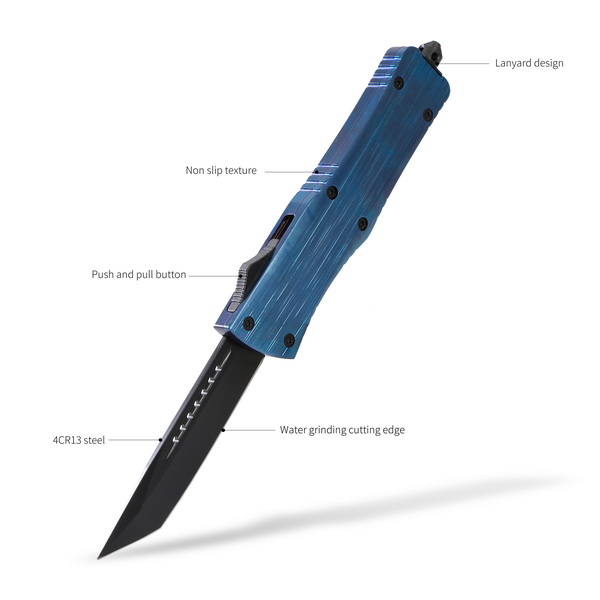

Comfort and safety play major roles in an OTF knife's usability. Look for:

- Ergonomic handles shaped to fit the natural contours of the hand, reducing hand fatigue and improving grip on wet or gloved hands

- Textured surfaces or inlaid grip materials to prevent slipping

- Secure finger guards or flippers enhancing control and preventing accidental cuts

- Reliable pocket clips for secure carry and easy access

- Lanyard holes for added carrying options and security during active use

Proper ergonomics not only improve performance but also reduce the risk of injury, especially during prolonged or heavy-duty use.

Reputable manufacturers implement rigorous quality assurance protocols, which may include:

- Sharpness testing to ensure the blade achieves factory edge standards

- Corrosion resistance evaluations to verify the effectiveness of steel and coatings against rust

- Mechanism endurance tests simulating thousands of open-close cycles without loss of reliability

- Stress and impact tests to examine handle and blade durability under extreme conditions

Each batch leaving the factory should meet these quality benchmarks, offering customers peace of mind they are purchasing a dependable tool.

Custom OTF knives cater to a wide variety of users and styles. Common options include:

- Tactical knives with non-reflective finishes, ideal for law enforcement or military use

- Collector's knives featuring artistic engraving, unique handle materials, and limited-edition designs

- Outdoor and utility knives optimized for activities like camping, hunting, or survival, with features like serrated edges or glass breakers

Customization allows clients to select blade profiles, handle materials, colors, coatings, and accessories to create knives that stand apart in function and appearance.

When shopping for a custom OTF knife, consider the following factors:

1. Intended Use: Define whether the knife is for tactical, utility, outdoor, or collection purposes to prioritize necessary features.

2. Material Preferences: Select steel and handle materials based on environmental exposure and maintenance willingness.

3. Size and Weight: Ensure the knife fits comfortably in your hand and pocket, balancing portability with usability.

4. Brand Credibility: Partner with trusted OEM manufacturers like Yangjiang Ruizhen known for quality and customization.

5. Warranty and Support: Confirm after-sales service policies covering repairs, replacements, or defects.

Choosing thoughtfully helps you find a knife perfectly suited to your needs.

Selecting a high-quality custom OTF knife requires an understanding of materials, mechanism engineering, ergonomics, and production standards. Yangjiang Ruizhen Industry and Trade Co., Ltd. excels at providing OEM custom OTF knives tailored to the precise demands of brands, wholesalers, and manufacturers worldwide.

With careful attention to blade steel, handle composition, smooth deployment mechanisms, and rigorous quality controls, our knives deliver unmatched performance, safety, and longevity. By following this comprehensive buyer's checklist, you can confidently select a custom OTF knife that combines functionality, style, and reliability.

High-quality stainless steels like S35VN, M390, and CTS-204P are preferred for their durable edge retention and corrosion resistance, making them ideal for outdoor conditions.

Yes, custom OTF knife manufacturers usually allow complete customization of blade shape, length, grind type, and finish to fit your brand's vision.

Regular cleaning of the blade channel and application of light lubricants are essential. Avoid dirt buildup and moisture ingress to keep the mechanism smooth.

Knife laws vary widely by location. Always check local, state, and national regulations to ensure compliance before purchasing or carrying an OTF knife.

Depending on complexity, customization level, and order size, production usually takes 4–8 weeks. It is recommended to confirm lead times when placing an order.

How to Verify Authenticity and Quality in Automatic OTF Knife Purchases

Choosing an Automatic OTF Knife for Tactical vs Everyday Use

The Benefits of Same-Day Shipping When Ordering Automatic OTF Knives

What Sets Premium Automatic OTF Knives Apart From Budget Alternatives

How to Maintain Peak Performance of Your Automatic OTF Knife

What Consumers Should Know About Automatic OTF Knife Blade Deployment

Customization Options in Automatic OTF Knives: OEM and ODM Explained