Views: 222 Author: Leah Publish Time: 2025-10-21 Origin: Site

Content Menu

● Introduction to Ruizhen's Mastery in Custom OTF Knives

● What Makes Custom OTF Knives Unique?

● Ruizhen's Cutting-Edge Manufacturing Process

>> Heat Treatment and Blade Hardening

● Innovation in Blade Materials and Designs

>> Blade Styles and Cutting Edge Innovations

● Customizable Features Delivering User-Centric Solutions

>> Branding and Personalization

● Environmentally Responsible Manufacturing

>> Scalability and Flexibility

>> Global Logistics and Support

● Ruizhen's Response to Market Trends

● Frequently Asked Questions (FAQ)

>> 1. What Are Custom OTF Knives?

>> 2. How Does Ruizhen Ensure the Quality of Their Custom OTF Knives?

>> 3. Can Ruizhen Provide Small Batch OEM Services?

>> 4. What Materials Does Ruizhen Use for OTF Knife Blades?

>> 5. How Can I Customize My OTF Knife Order with Ruizhen?

In the evolving world of outdoor gear, the demand for high-quality, reliable knives continues to rise. For enthusiasts, professionals, and collectors alike, the custom OTF (Out-The-Front) knife holds a special place due to its unmatched convenience and craftsmanship. Yangjiang Ruizhen Industry and Trade Co., Ltd., a Chinese cutting-edge outdoor knife factory, is a leading figure in this niche, delivering OEM services to foreign brands, wholesalers, and manufacturers worldwide. This article explores how Ruizhen consistently pushes the boundaries of innovation in custom OTF knives and why it is a preferred partner in the global market.

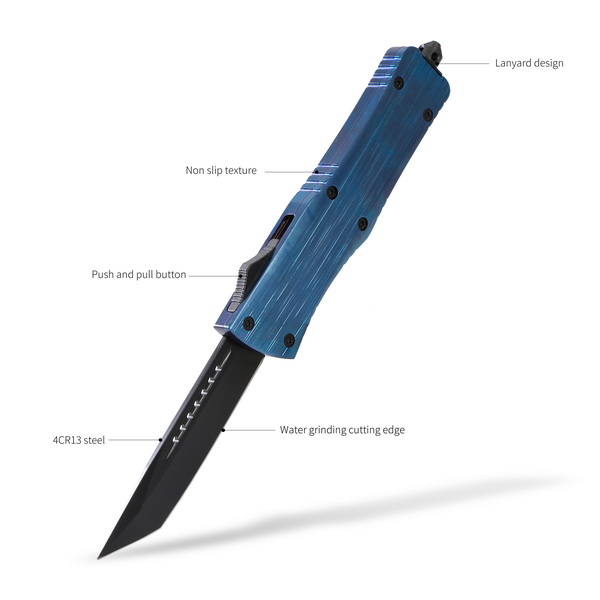

Custom OTF knives are characterized by their blade deployment mechanism, allowing the blade to slide out from the front of the handle through a spring-loaded system. This design enhances quick accessibility and security, ideal for tactical, survival, and everyday use.

- Precision engineering ensures smooth blade deployment.

- Durable materials provide long-lasting performance.

- Customizable features reflect user preferences and brand identity.

The mechanism behind an OTF knife is not only innovative but also demands precise functionality, which distinguishes it from conventional folding or fixed-blade knives. This specialization requires expertise in mechanics and design innovation, areas where Ruizhen excels.

At the core of Ruizhen's success lie advanced manufacturing techniques combined with expert craftsmanship.

The factory utilizes high-end CNC machines that ensure blade components are crafted with microscopic precision. This process minimizes waste material and guarantees repeatability crucial for OEM clients.

Each blade undergoes a meticulous heat treatment process to enhance hardness and flexibility. This not only extends the edge retention but also ensures the blade can withstand rigorous outdoor use without becoming brittle or prone to chipping.

Ruizhen implements a series of multi-stage inspections to detect flaws early in production. They use precision measuring tools and functionality checks, including blade deployment smoothness and lock strength tests, ensuring every custom OTF knife leaving the facility matches the highest standards.

Ruizhen invests strongly in R&D, exploring innovative materials and blade shapes that maximize the utility and aesthetics of custom OTF knives.

- Various grades of stainless steel like S35VN and D2 provide excellent corrosion resistance and edge retention.

- High carbon steels offer greater toughness for more demanding tactical uses.

- Specialized coatings such as titanium nitride and DLC (Diamond-Like Carbon) lend durability and reduce reflectivity, important for tactical and military applications.

Ruizhen offers customers multiple blade styles tailored for different outdoor and tactical applications, including tanto, drop point, clip point, and spear point blades. Each design considers factors such as penetration, slicing ability, and overall knife balance.

Customization forms the cornerstone of Ruizhen's offering, supporting foreign brands and consumers seeking tailored products.

- Durable composites like G10 and Micarta for superior grip.

- Lightweight aluminum alloys for strength-to-weight balance.

- High-tech carbon fiber for premium aesthetics and toughness.

Ruizhen works closely with clients to create handles engineered for maximum comfort and control based on ergonomic research and user feedback.

Logo engraving, unique color schemes, and specialized finishes allow brands to establish identity and recognition in competitive markets. Ruizhen supports these modifications seamlessly within its OEM workflow.

Recognizing global consciousness about sustainability, Ruizhen integrates eco-friendly processes into their production. They optimize material usage to reduce waste, recycle scrap materials where feasible, and adopt environmentally safe chemicals and finishes to minimize pollution.

Ruizhen offers comprehensive OEM services tailored to brand partners, wholesalers, and manufacturers worldwide.

From custom prototype development to high-volume production runs, Ruizhen adapts production capacity swiftly, enabling clients to respond to changing market demands.

Ruizhen's logistics network ensures timely delivery and minimizes disruptions, supporting clients' need for dependable supply chains.

By leveraging automation and process optimization, Ruizhen maintains competitive pricing to deliver cost-effective solutions without compromising product quality.

Understanding outdoor knife markets' ever-changing dynamics, Ruizhen actively follows and anticipates industry trends.

- Rising demand for tactical and survival knives has prompted Ruizhen to enhance blade strength and deployment reliability.

- Growth in eco-conscious consumerism drives the adoption of environmentally safer manufacturing methods.

- Ruizhen explores smart knife concepts incorporating blade status sensors or safety interlocks, blending traditional craftsmanship with new technology.

Yangjiang Ruizhen Industry and Trade Co., Ltd. stands at the forefront of custom OTF knife innovation through its fusion of advanced manufacturing technology, user-centered customization, and strict quality standards. Their capability to deliver precision-engineered, durable, and aesthetically refined knives has made them an industry leader servicing foreign brands and global wholesalers. As outdoor activities continue to grow in popularity worldwide, Ruizhen's dedication to innovation and sustainability ensures they will remain a trusted name in custom OTF knives for years to come.

Custom OTF knives feature blades that slide out from the front of the handle using spring mechanisms, designed to meet specific user or brand requirements, including blade shape, materials, handle design, and finishing.

Ruizhen employs multi-stage inspections, including precision measuring, functional tests for blade deployment and locking mechanisms, and environmental testing to verify durability under varying conditions.

Yes. Ruizhen's flexible manufacturing system accommodates both small batch prototypes and large-scale production orders, making them accessible to a wide range of clients.

Materials include premium stainless steel grades like S35VN and D2, high carbon steels, and specialized coated options such as titanium nitride and DLC for enhanced durability and performance.

Customization options cover blade design, handle materials and ergonomics, engraving, color schemes, and finishes. Clients work directly with Ruizhen's design team to create tailored solutions matching their vision.

How to Verify Authenticity and Quality in Automatic OTF Knife Purchases

Choosing an Automatic OTF Knife for Tactical vs Everyday Use

The Benefits of Same-Day Shipping When Ordering Automatic OTF Knives

What Sets Premium Automatic OTF Knives Apart From Budget Alternatives

How to Maintain Peak Performance of Your Automatic OTF Knife

What Consumers Should Know About Automatic OTF Knife Blade Deployment

Customization Options in Automatic OTF Knives: OEM and ODM Explained