Views: 222 Author: Leah Publish Time: 2025-12-01 Origin: Site

Content Menu

● What Is an Automatic OTF Knife?

● Premium vs Budget: The Core Divide

● Blade Steel and Heat Treatment

● Mechanism Precision and Reliability

● Safety Features and Locking Systems

● Ergonomics, Handle Materials, and Grip

● Tolerances, Blade Play, and Actuation Feel

● Durability and Real‑World Use

● Design Options and Blade Geometries

● Finishes, Coatings, and Visual Appeal

● Legal Context and Market Positioning

● Customization and OEM Opportunities

● Quality Control and Testing Standards

● Price, Value, and Customer Expectations

● Working With a Chinese OEM Factory

● Key Advantages of Premium Automatic OTF Knives for Your Brand

● FAQ

>> 1) Are Automatic OTF Knives safe for everyday use?

>> 2) What is the main difference between single‑action and double‑action Automatic OTF Knives?

>> 3) Why do premium Automatic OTF Knives cost more than budget models?

>> 4) How should an Automatic OTF Knife be maintained?

>> 5) Can my brand customize a premium Automatic OTF Knife through OEM production?

Premium Automatic OTF Knives stand apart from budget alternatives through superior materials, precise engineering, safer mechanisms, and reliable long‑term performance. For brands and wholesalers working with an OEM factory in Yangjiang, premium Automatic OTF Knife projects also mean stronger positioning, higher margins, and better user satisfaction.

An Automatic OTF Knife (Out‑The‑Front knife) is a switchblade whose blade deploys linearly out of the front of the handle using a spring‑loaded mechanism activated by a button or sliding switch. This out‑the‑front design enables rapid, one‑handed deployment, which is especially valuable in emergency, tactical, and outdoor scenarios where speed and control matter.

Many modern Automatic OTF Knives use double‑action mechanisms, meaning the same control both deploys and retracts the blade, while single‑action designs auto‑deploy but require manual resetting. Both styles rely on carefully tuned internal parts—springs, tracks, and locking interfaces—to ensure repeatable performance and safe operation.

Premium Automatic OTF Knives distinguish themselves in several ways: higher‑grade blade steels, better heat treatment, reinforced handles, tighter machining tolerances, and more robust safety systems. Budget Automatic OTF Knife models often save cost through lower‑end steels, basic plastics, simplified mechanisms, and lighter quality control, which can lead to blade wobble, dull edges, and inconsistent deployment over time.

For OEM buyers and brand owners, these differences translate directly into perceived value. A premium Automatic OTF Knife may cost more to produce, but it usually brings fewer returns, better reviews, and a stronger reputation, making it easier to justify higher retail prices and build long‑term customer loyalty.

Blade steel is one of the most critical elements separating premium from budget Automatic OTF Knife designs. Higher‑end OTF models often use performance steels that balance hardness, edge retention, toughness, and corrosion resistance, then apply controlled heat treatment to unlock that potential. Properly treated steel holds a sharp edge longer, resists chipping, and withstands repeated deployment and outdoor exposure.

Budget Automatic OTF Knife blades tend to rely on basic stainless or low‑carbon steels that sharpen easily but dull quickly and may rust more readily. For an OEM brand looking to position a knife as a serious outdoor or tactical tool, clearly specifying steel type and heat‑treat target hardness is essential. It helps transform an Automatic OTF Knife from a novelty item into a reliable cutting instrument.

The internal mechanism is the beating heart of an Automatic OTF Knife. Premium designs use precisely machined blade channels, hardened internal components, and carefully tuned springs so the blade deploys and retracts sharply, with a consistent "snap" and strong lock‑up. Good engineering minimizes misfires, partial deployments, and sluggish action.

By contrast, many budget Automatic OTF Knife models suffer from rough interior surfaces, weaker springs, and loose mechanisms that can lead to misfires or failure to lock fully. After some use, users may notice that the blade no longer fires with authority or begins to stop short of the locked position. For professionals, first responders, or serious outdoor users, this kind of inconsistency is unacceptable, which is why they gravitate toward premium OTF mechanisms.

Safety is a major area where premium Automatic OTF Knives justify their higher price tag. Well‑designed OTF models integrate clear, positive‑feeling safety switches, secure internal locks, and mechanisms that "fail safe" when the blade encounters an obstacle during deployment. Many double‑action designs are purposely engineered so the blade loses energy and stops rather than piercing through unexpected objects.

Budget Automatic OTF Knife designs may provide only the basic lock inherent in the mechanism, with minimal attention to redundant safeties or ergonomic control placement. Slippery switches, weak detents, and vague lock engagement can create a higher risk of accidental activation or incomplete lock‑up. For brands that care about long‑term reputation, investing in better safety engineering is one of the most important decisions when specifying a premium Automatic OTF Knife.

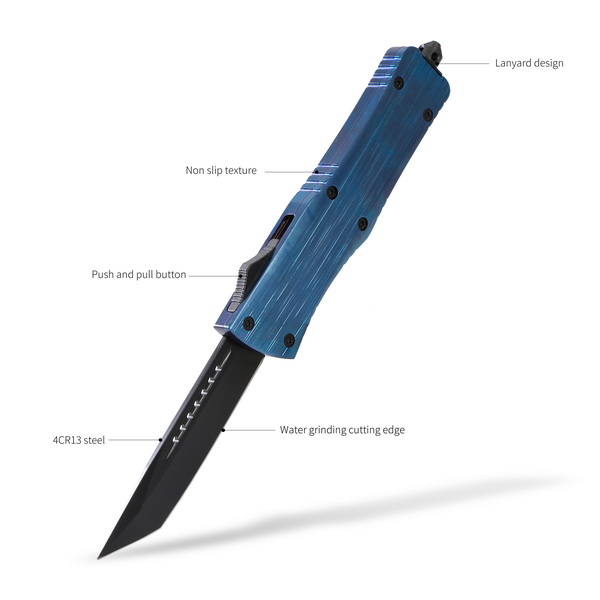

Handle design dramatically influences how an Automatic OTF Knife feels and performs in real use. Premium models frequently employ aircraft‑grade aluminum, reinforced polymer, or steel frames with textured surfaces and chamfered edges. These materials allow precise shaping, comfortable contours, and durable finishes that resist wear while providing secure traction in wet or gloved hands.

Budget Automatic OTF Knife handles often rely on thin cast metals or generic plastics with basic or cosmetic texturing. Over time, these can feel cheap, become slippery, crack, or chip under impact. For OEM projects, upgrading handle material and ergonomics is one of the most visible ways to signal premium quality. It also opens up space for creative features such as anti‑slip milling, finger grooves, glass breakers, and lanyard points.

Enthusiasts immediately notice how tightly an Automatic OTF Knife locks up and how it feels when actuated. A premium OTF typically exhibits minimal blade play in the open position, a clean, authoritative lock‑up sound, and a smooth but confident resistance on the slider or button. These qualities come from tight machining tolerances and consistent assembly.

Lower‑tier Automatic OTF Knife models often rattle when shaken, and their blades may wiggle noticeably side‑to‑side or vertically when open. The slider may feel gritty, loose, or overly stiff due to uneven machining or low‑quality internal parts. While a budget OTF might "work", it lacks the refined, precise feel that users associate with professional gear. This subjective impression can be crucial for brand image, especially in the tactical and enthusiast market.

Premium Automatic OTF Knives are designed to endure thousands of deployment cycles, environmental stress, and occasional abuse. Tough blade steels, corrosion‑resistant hardware, reinforced handle construction, and fine‑tuned springs all contribute to long service life. These knives are made for field use—cutting rope, packaging, straps, or emergency materials—without quickly loosening or failing.

Budget Automatic OTF Knife models may work fine out of the box but often show their limits after repeated use. Springs can lose strength, screws may back out, and cheaper materials can deform under stress. For brands that target professionals, outdoor enthusiasts, or collectors who use their gear, long‑term reliability is a non‑negotiable attribute and a key reason to invest in premium specifications.

Premium Automatic OTF Knives usually offer a wider range of blade shapes and design details than budget alternatives. Tanto, dagger, drop‑point, and clip‑point profiles are common, each suited to different cutting roles—piercing, slicing, or versatile everyday tasks. Higher‑end models may feature refined grinds, swedges, or partial serrations tailored to specific markets.

Budget Automatic OTF Knife lines tend to repeat a limited set of simple shapes to reduce tooling costs, and small design flaws in geometry or grind symmetry are more common. For OEM brands, collaborating on blade design is an opportunity to differentiate. A well‑designed blade profile, combined with the right steel and heat treatment, can turn a standard Automatic OTF Knife into a recognizable signature product.

Finishes and coatings significantly influence both performance and aesthetics. Premium Automatic OTF Knives may use advanced coatings or surface treatments that improve corrosion resistance, reduce glare, and hide wear. Anodized handles, two‑tone blades, stonewash textures, and detailed laser engravings can all elevate the perceived value of an Automatic OTF Knife.

Budget Automatic OTF Knife finishes are often simple paint or basic plating that can scratch or peel quickly. Logos may be printed rather than deeply engraved, and color options are usually limited. For a brand that wants to stand out on crowded digital shelves, premium finishing and consistent branding across a full Automatic OTF Knife line can be more persuasive than aggressive pricing alone.

Automatic OTF Knives are subject to legal restrictions in some countries and regions, influencing blade length, locking type, and marketing claims. Premium brands usually tailor their Automatic OTF Knife designs and product information to comply with relevant regulations while clearly communicating intended purpose, such as professional use, rescue, or lawful everyday carry.

Budget Automatic OTF Knife products may be marketed generically, with little attention to legal nuance, leaving buyers to research compliance themselves. For international brands and wholesalers, working closely with an experienced factory to adjust blade length, tip style, and packaging warnings helps protect both the end user and the brand image, especially when introducing a premium Automatic OTF Knife into a new market.

One of the biggest advantages of premium Automatic OTF Knife production is the scope for customization. Brands can specify unique blade shapes, edge configurations, coatings, handle materials, colors, and surface textures. They can also integrate logos through laser engraving, etching, or custom inlays, and coordinate packaging, sheaths, and accessories to create a coherent product family.

Specialized manufacturers in Yangjiang with experience in outdoor and tactical knives can provide OEM services that translate a brand concept into a tangible Automatic OTF Knife line. By combining local production advantages with international design direction, overseas brands can launch distinctive products that compete directly with established global names, while retaining flexibility in pricing and specification.

Premium Automatic OTF Knives are backed by stronger quality control systems. Typical checks may include visual inspection for cosmetic defects, measurement of key dimensions, repeated deployment tests, lock‑up verification, and edge sharpness testing. Some factories also run random stress tests, such as drop testing or exposure to dust and moisture, to ensure reliability.

In contrast, budget Automatic OTF Knife production may rely on simpler sampling or visual checks only, resulting in a higher chance of receiving knives with inconsistent deployment, misaligned parts, or cosmetic flaws. For OEM brands, demanding written quality standards and clear acceptance criteria is crucial. It ensures that each Automatic OTF Knife meets the expected performance level before reaching the market.

While premium Automatic OTF Knives are more expensive to produce, they often deliver better lifetime value. Customers who choose a higher‑end Automatic OTF Knife expect it to feel solid, function flawlessly, and last for years of regular use. When these expectations are met, they are more willing to recommend the product and remain loyal to the brand.

Budget Automatic OTF Knife buyers may be satisfied initially, but problems such as misfires, dull blades, or cracked handles can quickly turn a low price into a source of disappointment. For wholesalers and brand owners, balancing entry‑level options with clearly differentiated premium Automatic OTF Knife lines is often the most effective strategy. It allows price‑sensitive customers to enter the brand ecosystem while highlighting what makes the premium models truly special.

For foreign brand owners, wholesalers, and knife companies, partnering with a dedicated Chinese OEM factory in Yangjiang offers several advantages. The city is a well‑known knife‑manufacturing hub with mature supply chains, experienced technicians, and efficient production workflows. By collaborating closely with such a factory, a brand can turn a conceptual specification into a fully realized premium Automatic OTF Knife product.

A typical OEM process includes defining target market and price level, choosing blade steel and handle material, specifying mechanism type (single‑action or double‑action), and setting clear requirements for deployment feel, safety features, and packaging. Samples are then produced for evaluation and testing. Once approved, volume production begins under agreed‑upon quality standards, ensuring consistency across each Automatic OTF Knife batch.

For overseas partners working with a Yangjiang factory, premium Automatic OTF Knives provide multiple strategic benefits:

- Higher perceived value: Better materials, refined mechanisms, and clean finishing immediately signal quality to end users.

- Stronger differentiation: Customized blades, finishes, and branding help your Automatic OTF Knife stand out in a crowded market.

- Improved reputation: Reliable, safe, and durable knives reduce return rates and support positive reviews.

- Long‑term scalability: Once a premium Automatic OTF Knife line proves successful, it can be expanded with new sizes, colors, and limited editions.

By positioning premium Automatic OTF Knives at the top of your product hierarchy, you create a flagship series that defines your brand's standard of performance and design.

Premium Automatic OTF Knives distinguish themselves from budget alternatives through better blade steels, more precise mechanisms, enhanced safety systems, superior ergonomics, and rigorous quality control. These attributes translate into real‑world advantages: stronger lock‑up, smoother deployment, longer edge life, and far greater reliability under demanding conditions. For international brands, wholesalers, and producers collaborating with an experienced OEM factory in Yangjiang, investing in premium Automatic OTF Knife designs is an effective way to elevate product lines, protect brand reputation, and meet the expectations of serious outdoor, tactical, and everyday‑carry users.

Yes, an Automatic OTF Knife can be safe for everyday use when it is well designed and used responsibly. Look for models with clear safety switches, reliable locks, and a mechanism that stops the blade if it meets resistance, and always keep fingers and objects away from the blade's path during deployment.

A single‑action Automatic OTF Knife automatically deploys the blade when activated but requires manual retraction before it can be fired again. A double‑action Automatic OTF Knife uses the same control to both extend and retract the blade, offering faster reset and greater convenience for frequent use.

Premium Automatic OTF Knives cost more because they use higher‑grade materials, more complex machining, tighter tolerances, and stronger quality control. These factors increase production cost but lead to better performance, improved safety, longer service life, and a more refined user experience.

To maintain an Automatic OTF Knife, keep the blade clean and lightly oiled, periodically wipe the handle, and avoid using the knife as a pry bar or screwdriver. If the mechanism becomes sluggish, follow manufacturer instructions for cleaning and, when allowed, apply a small amount of suitable lubricant to keep deployment smooth.

Yes, OEM production allows extensive customization of a premium Automatic OTF Knife, including blade shape, steel type, finishes, handle materials, colors, grip patterns, logos, and packaging. By defining clear specifications and working closely with a specialized factory, your brand can launch a unique, high‑value Automatic OTF Knife line tailored to your target market.

[1](https://www.budk.com/Damascus-Iridescent-Dagger-The-Premium-Automatic-O-52421/52421.html)

[2](https://blade-city.com/collections/otf-knives)

[3](https://www.benchmade.com/products/4600dlc)

[4](https://cobratecknives.com/product/special-purpose/utility-knives/otf-utility-knife/)

[5](https://www.kennesawcutlery.com/Dagger-Automatic-OTF-Damascus-Blade-Knife-Sta-52319/DADB.html)

[6](https://ocasoknives.com/products/lucent-automatic-otf-black-large)

[7](https://templarknife.com/products/templar-knife-premium-weighted-come-and-take-it)

[8](https://kaswords.com/premium-gold-automatic-dual-action-otf-knife-heavy-duty-zinc-alloy-with-decorative-gold-blade/)

[9](https://kershaw.kaiusa.com/livewire-tanto.html)

[10](https://www.youtube.com/watch?v=mk0jqi3VmUg)

How to Verify Authenticity and Quality in Automatic OTF Knife Purchases

Choosing an Automatic OTF Knife for Tactical vs Everyday Use

The Benefits of Same-Day Shipping When Ordering Automatic OTF Knives

What Sets Premium Automatic OTF Knives Apart From Budget Alternatives

How to Maintain Peak Performance of Your Automatic OTF Knife

What Consumers Should Know About Automatic OTF Knife Blade Deployment

Customization Options in Automatic OTF Knives: OEM and ODM Explained