Views: 222 Author: Leah Publish Time: 2025-11-04 Origin: Site

Content Menu

● What Defines a Tactical OTF Knife?

● The Engineering Behind Tactical OTF Knives

● Technical Specifications: Key Blade Considerations

>> Blade Steel and Edge Options

>> Blade Length

● Handle Materials and Ergonomics

● Why OTF Knives Dominate Tactical and EDC Use

>> Versatility

● Affordable Quality: OEM Manufacturing in China

● What to Avoid: Pitfalls in Budget Tactical OTF Knives

● Popular Models and Customization Highlights

● Maintenance and Longevity Tips

● Frequently Asked Questions (FAQ)

>> 1. What distinguishes single-action from double-action tactical OTF knives?

>> 2. Are tactical OTF knives legal to own and carry?

>> 3. What are the best blade steels for budget tactical OTF knives?

>> 4. How can brand owners ensure they're sourcing quality OTF knives from Chinese OEMs?

>> 5. How should tactical OTF knives be maintained for long-term reliability?

Finding Tactical OTF Knives that offer both outstanding quality and affordability is more achievable than ever for global buyers. As Chinese OEM factories continue to innovate with advanced materials and strict quality controls, overseas brands, wholesalers, and manufacturers are able to source budget tactical OTF knives that fit a range of tactical and everyday carry (EDC) needs. This guide explores what makes these knives so desirable, how to evaluate their construction, and why partnering with experienced manufacturers creates endless opportunities for quality custom knives.

Tactical OTF knives, or Out-The-Front knives, deploy their blades straight from the handle's front using a button or sliding mechanism. Unlike folding knives, their direct-action deployment enables exceedingly rapid, one-handed opening—crucial in high-stress situations, law enforcement, rescue operations, or defense. This efficiency has made them a favorite across tactical professions and a premium choice for EDC enthusiasts.[1][2][4]

These knives fall into two main categories:

- Single-Action OTF Knives: The blade deploys automatically, usually via a strong spring, but must be manually retracted after use. These knives have fewer moving parts, offering reliable deployment, greater mechanical simplicity, and reduced risk of malfunction.

- Double-Action OTF Knives: Both deployment and retraction are achieved using the same switch or slider, providing true one-handed operation. Double-action OTF knives are praised for convenience, efficiency, and their suitability for tactical professionals who may need to rapidly operate the tool multiple times in a row.[2][4][6][1]

Central to the tactical OTF knife is its precisely engineered spring system. Typically made of high-carbon steel, the internal spring stores energy when the blade is retracted. When the user activates the knife, this stored energy propels the blade forward. In quality models, this system is meticulously calibrated to ensure reliable, fast deployment every time. The track mechanism—a channel inside the handle—guides the blade smoothly, preventing misalignment or sticking during operation.[1]

Safety is paramount. Most tactical OTF knives use either:

- Ball-bearing locks: Steel balls engage with the blade carrier, holding the blade securely.

- Mechanical locks: Machined interlocking parts ensure robust blade retention during rigorous use.

- Friction-based locks: Some budget designs use friction to maintain blade position; adequate but less robust than mechanical or ball-bearing locks.[1]

In tactical applications, a strong lock is essential to prevent accidental closure during use, and quality knives from leading OEM manufacturers rigorously test for consistent locking and safe disengagement.

A blade carrier runs along tracks inside the handle, ensuring smooth and accurate movement. This precision is especially important in tactical OTF knives, where even slight misalignments can result in jams or reduced service life.[2][1]

The blade's material directly determines sharpness, edge retention, corrosion resistance, and toughness. Popular steels for budget tactical OTF knives include:

- D2 Steel: An affordable, tool-grade steel with impressive hardness, though it needs occasional oiling to guard against rust.

- AUS-8: Offers good corrosion resistance and decent edge durability, ideal for EDC applications.

- Stainless alloys (440C, 154CM): Often used for budget knives with an emphasis on easy maintenance and decent longevity.

- Premium steels (CPM-S30V, M390): Available from select OEMs for brands seeking an upgrade without massive cost hikes.[5][2]

Tactical OTF knives also come with various blade profiles:

- Drop Point: Versatile shape, well-balanced for slicing and piercing.

- Tanto: Reinforced tip for tactical piercing tasks.

- Dagger/Spear Point: Double-edged, ideal for defense and straight penetration.

- Serrated or Combo Edge: Adds extra cutting power for rope or tough materials, favored in rescue models.[7][5]

- 3 to 3.5 inches: The most common, versatile size for tactical and legal carry.

- Under 3 inches: Ultra-compact, suitable for strict legal jurisdictions.

- Over 4 inches: Maximized cutting performance but often restricted; best for military/tactical or specialty use.[5][1]

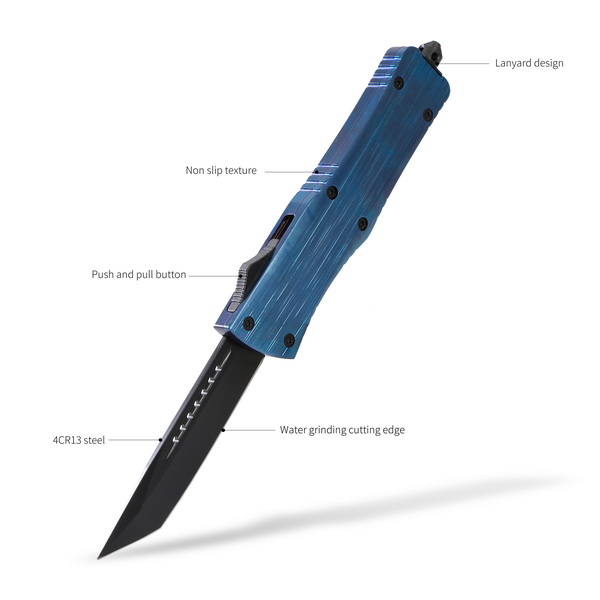

A tactical OTF knife's effectiveness depends on grip security, durability, and comfort. The most reliable options for budget-conscious buyers are:

- Aluminum (6061-T6 aircraft grade): Lightweight, durable, resists corrosion, and allows for a variety of surface finishes.

- G-10 Composite: Fiberglass laminate noted for grippy texture and strength.

- Polymer (FRN/GRN): Lightweight, affordable, and tough for hard use—even at lower price points.[4][5]

Premium factories offer handle enhancements:

- Textured or knurled grips for slip-resistance.

- Glass breakers, lanyard holes, and deep-carry clips as practical tactical features.

No other folding or fixed knife offers the direct, one-handed deployment of tactical OTF knives. Their design lets users go from safe carry to ready stance in mere moments—essential for first responders, law enforcement, and tactical operators who can't afford slow access.

Few knife types handle as diverse a range of cutting tasks as tactical OTF knives. From slicing webbing in a rescue, to opening packages, to rigorous field work, the right OTF knife blends utility and tactical readiness like no other.

Jurisdictions vary widely on OTF legality. Many regions allow OTF knives only under certain blade lengths (often up to 3.5 inches). Brands and buyers should always confirm local laws before making purchasing or distribution decisions.[5][1]

For international brands, wholesalers, and knife retailers, China's Yangjiang region and its established factories have transformed OEM and ODM tactical OTF knife production. These factories offer:

- Modern CNC and forging lines: Allowing precise machining of complex mechanisms.

- Custom branding: Logos, blade engraving, colored anodization, and personalized packaging.

- Rigorous quality controls: Factories certified to international standards like ISO9001, performing multi-stage QC to ensure reliability.

Using these supply chains, it's now possible to create tailored product lines that meet global buyers' demands for both budget and performance.[11][12]

Blade play—a slight side-to-side movement of the blade when open—is a reality for all OTF designs, but well-made knives hold play to a safe minimum through superior parts and tight tolerances.

The lowest-cost knives may use inferior steel prone to rust or deformation, or handles of weak, brittle plastic instead of aluminum or G-10. Reputable OEMs now supply technical data sheets and material certifications on request.

Cheaper internals may jam or misfire. Always request sample deployment videos, review testimonials, and examine return policies before major buys.

Leading value-driven tactical OTF knives include:

- Guardian Tactical Series: Praised for smooth action, tough handle, and competitive price.

- Kershaw Livewire: Accessible performance, USA-made reliability, budget-friendly.

- Smith & Wesson M&P OTF: Known globally for affordability, utility, and tactical design details.

- AKC F-16 & Boker Kalashnikov: Widely used and often customized by Chinese OEM suppliers for foreign brands.

OEM customization can include blade shape, serration, edge treatments (coated, stonewashed, mirror polish), handle colors, and multi-functional hardware such as glass breakers.

To extend the life of your tactical OTF knife:

- Regularly clean internal tracks and blade to avoid grit buildup; compressed air is ideal.

- Lightly oil pivot and spring mechanisms with lubricant designed for precision tools.

- Sharpen as needed using the correct angle for your blade steel—OTF knives benefit from regular stropping to retain a razor edge.[1][5]

Routine maintenance maximizes value and ensures deployment reliability even in tough environments.

Tactical OTF knives have redefined everyday carry and specialty tool standards across the globe, combining lightning-fast one-handed deployment with robust engineering, compact size, and tactical features. The evolution of advanced manufacturing—particularly from China's leading OEM factories—makes it possible to access budget tactical OTF knives that don't sacrifice reliability, safety, or custom branding. By understanding technical specifications, key materials, and the latest innovations, buyers and sellers alike can make informed decisions, ensuring the knives they choose withstand the demands of tactical use and personal defense.

Single-action OTF knives deploy the blade automatically, but manual retraction is required. Double-action OTF knives allow both deployment and retraction with the same actuator, providing seamless, full one-handed operation.[6][2][5]

Legality depends on local laws, often limited by blade length or model type. Most jurisdictions allowing automatic knives typically enforce a maximum blade length of 3–3.5 inches. Always check your local legal requirements before purchase.[5][1]

D2 and AUS-8 are the most popular for their good balance of hardness, durability, and price. For premium function, some OEMs also offer M390, CPM-S30V, and similar stainless alloys with exceptional sharpness and corrosion resistance.[5]

Look for factories with international certifications like ISO9001, request updated material certifications, demand high-quality sample photos and demonstration videos, and always verify previous customer feedback.[12][11]

Clean the internal track and blade regularly, lubricate the mechanism lightly, and sharpen only when needed using correct techniques for your steel type. Proper maintenance guarantees smooth operation and safe, reliable deployment.[1][5]

[1](https://knife-depot.com/blogs/sharpened-values/otf-knives-explained-the-complete-guide)

[2](https://www.selfdefensesupply.com/otf-knives-guide)

[3](https://ravencresttactical.com/otf-knife-buyers-guide/)

[4](https://bladeops.com/blog/otf-knife-buyers-guide/)

[5](https://bladeops.com/blog/otf-knife-buyers-guide-what-to-look-for-in-your-next-otf-knife/)

[6](https://www.tacticalsportinggoods.com/blogs/news/understanding-otf-knives-a-comprehensive-guide-to-their-features-and-uses)

[7](https://uppercuttactical.com/blogs/news/otf-plain-vs-serrated-edge-guide)

[8](https://www.stunster.com/blog/the-ultimate-guide-to-otf-out-the-front-knives/)

[9](https://www.youtube.com/watch?v=WN8PDfEbZw4)

[10](https://dnkknives.com/blog/what-you-need-to-know-about-otf-knives/)

[11](https://www.58hrcknives.com/top-10-tactical-otf-knives-manufacturers-in-china.html)

[12](https://www.58hrcknives.com/top-10-otf-pocket-knife-manufacturers-in-china.html)

How to Verify Authenticity and Quality in Automatic OTF Knife Purchases

Choosing an Automatic OTF Knife for Tactical vs Everyday Use

The Benefits of Same-Day Shipping When Ordering Automatic OTF Knives

What Sets Premium Automatic OTF Knives Apart From Budget Alternatives

How to Maintain Peak Performance of Your Automatic OTF Knife

What Consumers Should Know About Automatic OTF Knife Blade Deployment

Customization Options in Automatic OTF Knives: OEM and ODM Explained