Views: 222 Author: Leah Publish Time: 2025-11-27 Origin: Site

Content Menu

● Introduction: Why the Automatic OTF Knife is a Game Changer

● How the Automatic OTF Knife Works

>> The Internal Spring System: Heart of the Technology

>> Single-Action vs. Double-Action: Which is Best for You?

● Critical Blade Engineering and Materials

>> Premium Blade Steels for Automatic OTF Knife Performance

>> Blade Geometry and Edge Options

● Handle Design, Comfort, and Durability

>> Handle Materials and Ergonomics

>> Pocket Clip and Carry Options

● Essential Locking and Safety Mechanisms

>> Plunge Locks and Spring Tension Locks

● Deployment Speed and Reliability

>> The Advantage of Linear Motion

>> Spring Strength and Mechanical Precision

● Special Features for Tactical and Emergency Use

>> Rescue Tools and Multi-Functionality

● OEM Customization and Branding Opportunities

>> Why Work with a Chinese OEM Factory?

● Everyday Carry (EDC) and Tactical Scenarios

>> Storage and Legal Compliance

● Selecting the Right Automatic OTF Knife: A Buyer's Perspective

● Frequently Asked Questions (FAQ)

>> 1. What makes the Automatic OTF Knife different from traditional knives?

>> 2. What are the best blade steels for Automatic OTF Knives?

>> 3. Can Automatic OTF Knives be customized for private labels or OEM?

>> 4. How do you maintain an Automatic OTF Knife for long service life?

>> 5. Are Automatic OTF Knives legal for import and carry worldwide?

The Automatic OTF Knife, or Out-the-Front Knife, has rapidly become a preferred choice among outdoor professionals, military and law enforcement officers, EDC enthusiasts, and collectors worldwide. Known for its fast-action blade deployment, tactical appearance, and unrivaled one-handed operator safety, this modern tool offers capabilities that traditional folding or fixed-blade knives cannot match. For international buyers, brands, and wholesalers, especially those interested in high-quality OEM production from leading Chinese factories, understanding the features, variants, and technical details of the Automatic OTF Knife is essential for making an informed purchase and building lasting partnerships with manufacturers.[2][4][5]

At the core of every Automatic OTF Knife lies a precision-engineered spring system. When the activation switch or button is pressed, stored energy in the high-carbon steel spring is released, forcing the blade forward in a direct, linear motion. In double-action models, the same mechanism retracts the blade, pulling it safely back into the handle. This engineering marvel distinguishes the Automatic OTF Knife from manual openers, offering speed and convenience with every use.[1][4][6]

There are two main categories:

- Single-Action Automatic OTF Knife: Blade deploys automatically at the press of a button but must be manually retracted to close. Favored for its simplicity, mechanical strength, and robust spring action, this type is often chosen for heavy-duty tactical and field use. It has fewer moving parts and hence lower failure rates in hostile environments.[4][5][2]

- Double-Action Automatic OTF Knife: Both blade deployment and retraction occur via the same actuator (usually a sliding switch or dual-point button). Renowned for user convenience and rapid repeat-action, double-action knives are prized by EDC users, emergency responders, and tactical operatives because they allow seamless blade control with fast retraction and redeployment.[5][6][7][2]

Choosing the correct blade material is vital for performance and durability. High-end Automatic OTF Knives utilize steel grades such as M390, CPM-S30V, D2, and AUS-8, each providing unique characteristics:

- M390: Outstanding edge retention and corrosion resistance, making it ideal for harsh environments.

- CPM-S30V: Combines toughness, wear resistance, and sharpness favored by professionals.

- D2: Offers excellent hardness and longevity; suitable for repeated heavy-duty use.

- AUS-8/154CM: Balanced sharpness with ease of maintenance and reasonable corrosion protection.[2][5]

Selecting the right blade geometry can make a significant functional difference:

- Single vs. Double-Edged Blades: Double-edged designs, often found in Automatic OTF Knives, are superior for thrusting and penetration, while single-edged models offer safer handling and versatile finger placement.[3]

- Blade Shapes: Common Automatic OTF Knife shapes include tanto, drop point, spear point, and dagger, each catering to distinct tactical or daily tasks.

- Edge Types: Serrated edges improve performance on fibrous materials, while plain edges excel in precision slicing.[4][5]

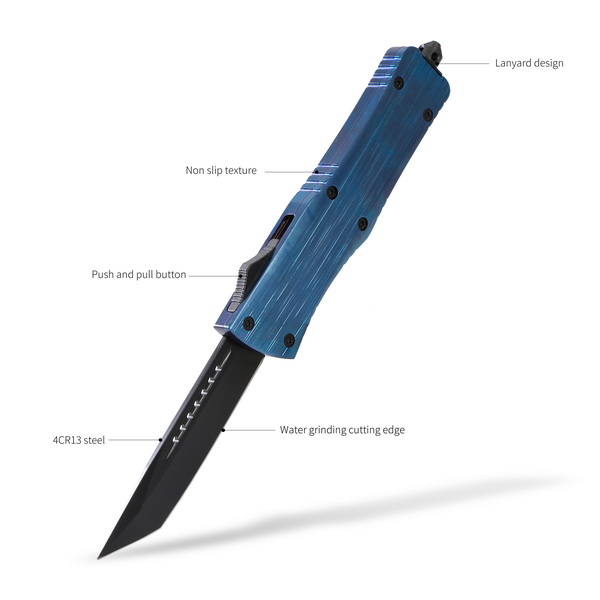

A premium Automatic OTF Knife features handles optimized for comfort, strength, and grip:

- 6061-T6 Aluminum: Lightweight, highly durable, and resists corrosion.

- G-10 Composite and Carbon Fiber: High rigidity, chemical resistance, and unique textures for secure handling.

- Stainless Steel and Polymer: Offer robust construction for budget-focused or high-abuse deployment models.

- Ergonomic Shapes: Finger grooves, anti-slip textures, and ambidextrous contours ensure secure, fatigue-free operation, crucial for wet or stressful conditions.

Modern design mandates:

- Deep-Carry Pocket Clips: For discreet, low-profile carry.

- Multi-Position Clips: Allow right or left-handed users to quickly deploy the Automatic OTF Knife from any orientation.

- Lanyard Holes and Glass Breakers: Add utility for rescue or tactical settings.[7][5][2]

Automated deployment requires advanced locking systems:

- Plunge Lock: Offers solid blade engagement under rigorous use.

- Spring Tension System: Maintains blade stability during both deployment and retraction.

- Safety Switches: Critical for pocket carry; prevents accidental deployments which could otherwise cause injuries or damage gear.[5][7][4]

The defining feature of an Automatic OTF Knife is its lightning-fast, straight-line action. Unlike folding knives that require additional manipulation, a quality OTF knife is ready for action in mere milliseconds—a vital edge during emergencies, tactical operations, or time-sensitive tasks.

- Sturdy Internal Springs: Ensure consistent, powerful blade action.

- Precision Machining: Higher-tolerance manufacturing (common in leading Chinese OEMs) eliminates blade rattle, improves longevity, and enables smooth operation for thousands of cycles.[1][4]

OEM Automatic OTF Knife factories often incorporate value-added functions for first responders, outdoor adventurers, and military clients:

- Glass Breaker: Hardened tip for vehicle escape.

- Seatbelt Cutter: Integrated hook for cutting through safety restraints quickly.

- Integrated Safety Systems: Prevent accidental deployment in extreme dynamic environments.

- Non-Slip Handles: Ensure grip retention in all weather or while wearing gloves.[2][5]

Partnering with an experienced Chinese OEM Automatic OTF Knife manufacturer means:

- Access to advanced production lines, high-precision CNC machines, and rigorous in-house QC practices.

- Flexibility for small or large batch orders, prototyping, and R&D innovations.

- Bespoke finishing—custom blade logos, handle colors, unique textures, and patent-worthy design features.

- Full-spectrum service, including compliance documentation for international trade.[11][12]

- Blade Engraving/Logo Etching: For private or white-label brands.

- Handle Color/Material: Meeting specific market demands (military, outdoor retail, collector, etc.).

- Safety and Mechanism Tuning: Tailored action force, spring resistance, and regulatory compliance.

- Accessory Bundling: Custom sheaths, storage cases, testing certifications on request.[11]

Automatic OTF Knives serve:

- Military and Law Enforcement: For instant deployment and fail-safe blade security.

- First Responders/Emergency Services: For seatbelt cutting, glass breaking, and precise interventions.

- Outdoor Enthusiasts: Hunters, campers, and hikers appreciate the rapid, single-handed access.

- Collectors: Covet rare blade steels, limited-run handle textures, and unique locking innovations.

- Quick rope or cordage cutting on construction, climbing, or marine settings.

- Hard-use scenarios in search & rescue, including disaster response where gloves or slippery hands make traditional knives less safe or useful.

- Everyday utility, such as box opening, slicing, and field repairs.[13][4][5][2]

For peak functionality, regular Automatic OTF Knife care involves:

- Internal cleaning—compressed air to remove debris.

- Blade lubrication—knife-specific lubricants recommended.

- Spring and Lock Inspection—routine checks for signs of fatigue or corrosion.

- Sharpening using ceramic or diamond rods; avoid power tools that can overheat high-performance steels.[4][5][2]

- Store dry, periodically activate the blade to ensure smooth operation and spring longevity.

- Be aware: OTF knife legality varies—check local and international regulatory status before importing or exporting.[2][4]

When sourcing OEM Automatic OTF Knives for private label, wholesale, or branded retail channels, prioritize:

- Mechanical reliability over cosmetic details.

- Documented material sources (steel grade authenticity).

- Use-case alignment (heavy duty, EDC, collectability, tactical law enforcement).

- Certifications (ISO, CE, specific export permits).

Ensure your Chinese OEM partner provides:

- Production documentation and sample evaluations.

- After-sales support and warranty structures.

- Transparent communication on lead times, batch inspection, and rework policies.

- Intellectual property protection for custom designs.

The Automatic OTF Knife blends unparalleled engineering, versatility, and rapid convenience, making it an essential choice for tactical operations, emergency rescues, collector portfolios, and everyday carry. Partnering with a capable Chinese OEM unlocks a spectrum of customizable options, from premium blade steels and ergonomic handles to robust safety features and global legal compliance. By understanding the intricate mechanics, selecting high-quality manufacturers, and specifying the technical details that matter to your audience or user base, your brand or organization will deliver Automatic OTF Knives that exceed expectations for function, safety, and innovation.

An Automatic OTF Knife deploys its blade linearly from the handle—via spring-loaded mechanism and push-button actuation—rather than swinging open or fixed. This enables much faster, safer one-handed use.[5][4][2]

Top automatic OTF knives feature M390, CPM-S30V, D2, or AUS-8 for maximum sharpness, edge retention, and corrosion resistance—even after extended use.[5][2]

Yes, leading Chinese OEM factories provide logo engraving, handle material/color, safety mechanism adjustments, and unique blade profiles to match the requirements of international brands, wholesalers, and distributors.[12][11]

Regular internal cleaning, blade lubrication, careful sharpening, and periodic spring tension checks will maintain both deployment speed and safety for years.[4][5]

Legal status varies; some countries and regions restrict sales, import, or everyday carry. Always research and comply with local knife regulations before shipment or use.[2][4]

[1](https://knife-depot.com/blogs/sharpened-values/otf-knives-explained-the-complete-guide)

[2](https://www.selfdefensesupply.com/otf-knives-guide)

[3](https://www.tektoknives.com/blogs/news/a-buyers-guide-to-automatic-knives)

[4](https://nobliecustomknives.com/what-is-an-otf-knife-and-how-does-an-otf-knife-work/)

[5](https://bladeops.com/blog/otf-knife-buyers-guide/)

[6](https://uppercuttactical.com/blogs/news/how-does-an-otf-knife-work)

[7](https://www.tacticalsportinggoods.com/blogs/news/understanding-otf-knives-a-comprehensive-guide-to-their-features-and-uses)

[8](https://www.stunster.com/blog/the-ultimate-guide-to-otf-out-the-front-knives/)

[9](https://www.youtube.com/watch?v=WN8PDfEbZw4)

[10](https://tacknivesusa.com/otf-knife-and-spring-design-key-elements-to-identify-when-deciding-to-buy/)

[11](https://www.58hrcknives.com/top-automatic-otf-knife-manufacturers-and-suppliers-in-america.html)

[12](https://upknives.com/products/oem-9-inch-tanto-otf-automatic-knifeotfd8007-bgd1-laser-etched-feather-design-ideal-for-hunting-tactical-outdoor-and-camping)

[13](https://tacknivesusa.com/the-benefits-of-buying-an-otf-knife/)

How to Verify Authenticity and Quality in Automatic OTF Knife Purchases

Choosing an Automatic OTF Knife for Tactical vs Everyday Use

The Benefits of Same-Day Shipping When Ordering Automatic OTF Knives

What Sets Premium Automatic OTF Knives Apart From Budget Alternatives

How to Maintain Peak Performance of Your Automatic OTF Knife

What Consumers Should Know About Automatic OTF Knife Blade Deployment

Customization Options in Automatic OTF Knives: OEM and ODM Explained